Agility and innovation

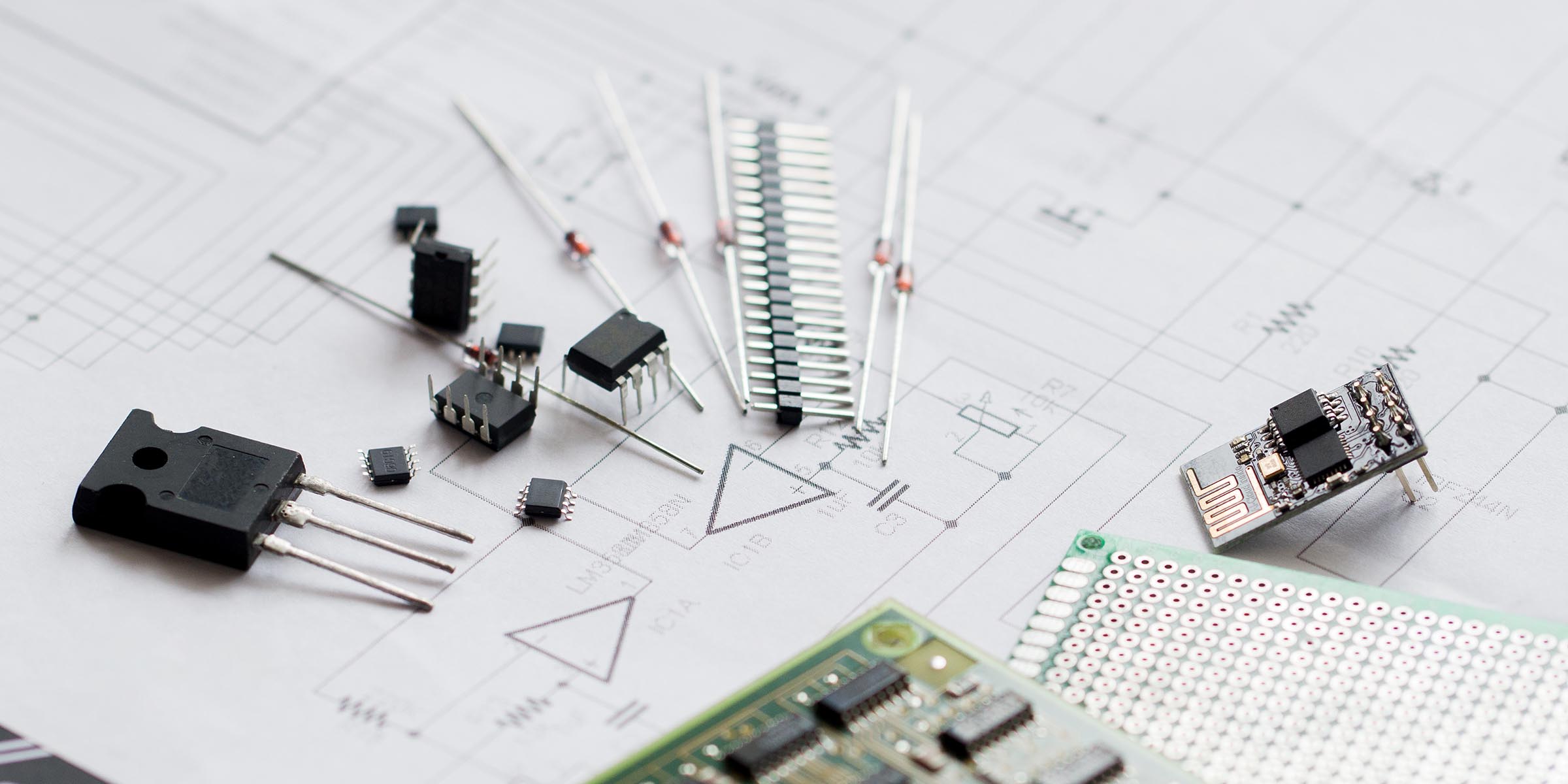

The electronics industry is a rapidly changing and dynamic sector, synonymous with innovation and the demand for very often complex parts and components manufactured to exacting tolerances, quickly and cost effectively. This — and the fact that there is a push for ever smaller microelectronics — shows why micrometal's Etching Group's photochemical etching process is a perfect fit.

The photochemical etching process is used to produce geometrically complex, often feature-rich electronic parts and components. However, electronics OEMs not only need to ensure micron-scale tolerances are achieved on such parts, but this accuracy sometimes has to be achieved given the safety-critical nature of many electronics applications.

Advantages and benefits for electronics

- High design freedom - you benefit from realizing geometric complexity.

- Costs do not increase with complexity - you benefit from competitive part prices regardless of their complexity.

- Achieve repeatable ultra-low tolerances - you benefit from accurate parts, from the first part to the millionth, supporting the longevity and quality of your applications.

- Multiple different parts are possible in each production run - you benefit from a high degree of flexibility even in volume production.

- Stress- and burr-free parts - you benefit from lfewer post-processing disturbances, which contributes to end-use product integrity and safety.

- Quickly manufacturable and cost-effective tools - you benefit from maximum flexibility to adapt to new conditions.

Applications

- Lead Frames

- Sensors

- Flat springs / bends

- Connectors

- Semiconductor components

- Shields

- Seals

- Washers

Cost-efficient Manufacturing

For most electronics OEMs, it's all about producing ever more functionality at ever lower cost in a highly competitive sector. To succeed, increasingly complex and innovative electronic parts and components must be manufactured, and this is where photo-chemical etching comes into its own. The ability to produce complicated metal parts with a technology that does not become more expensive with increased complexity, where the first part is the same as the millionth because there is no tool wear, and which can process a wide variety of metals is the key to success.