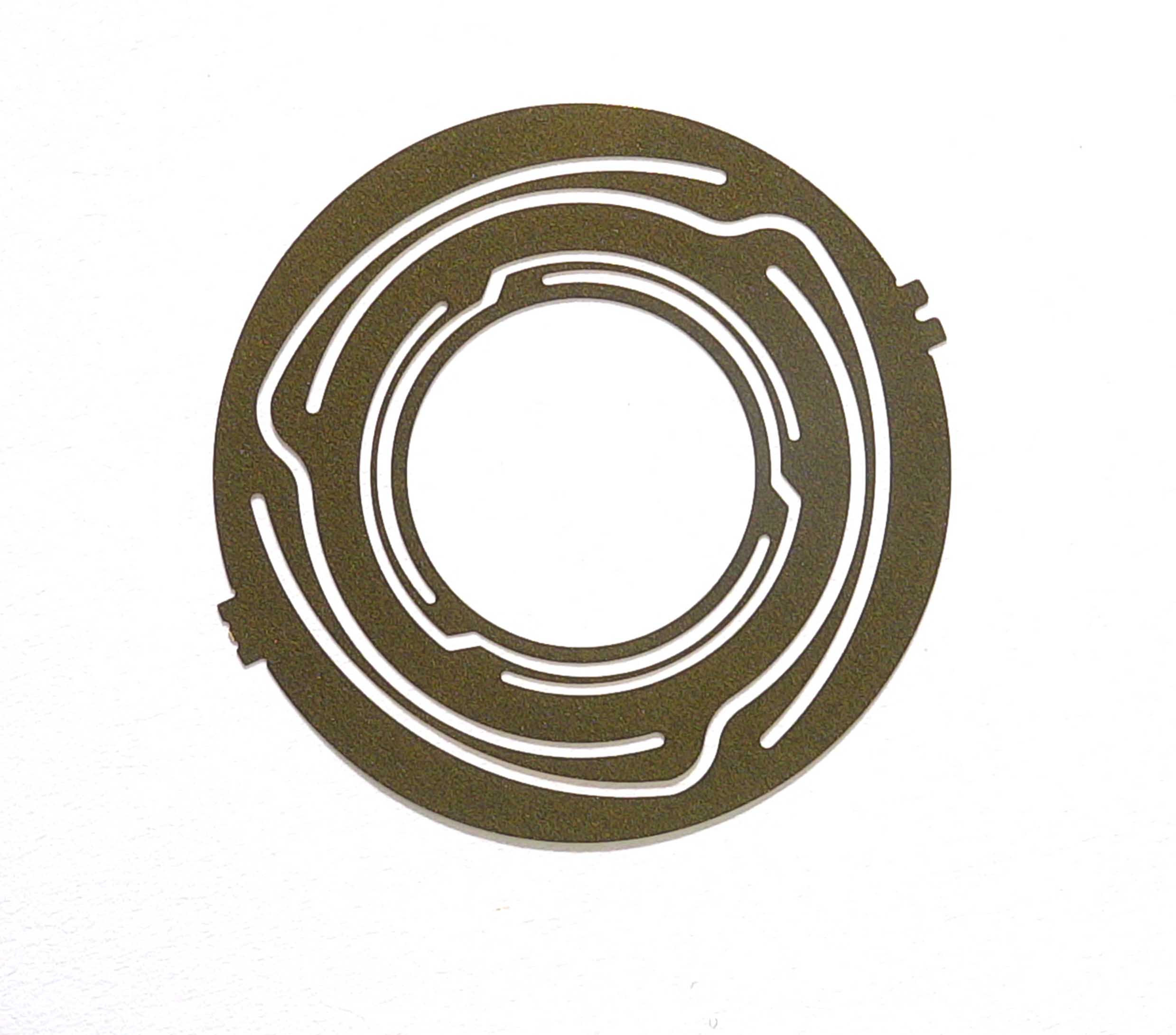

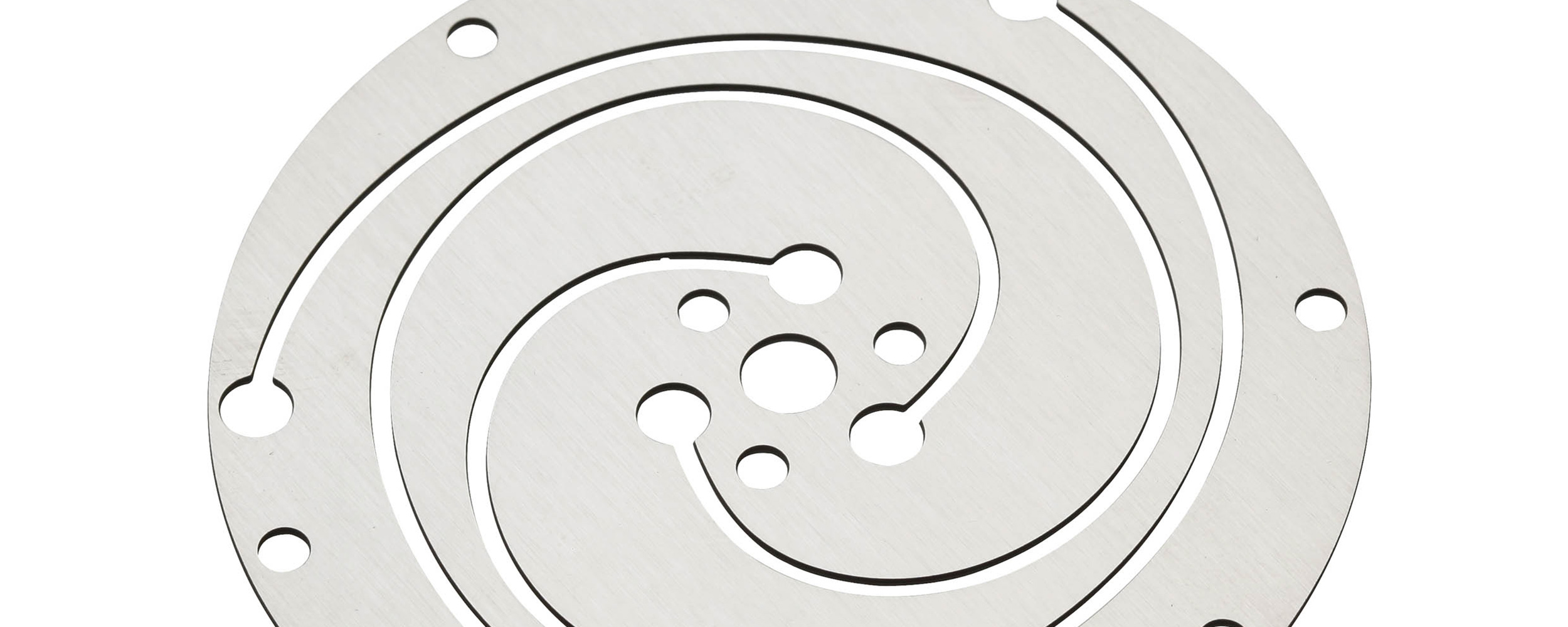

Complex washers & rings through etching

As everyone is aware, washers and rings have an important function in various assemblies. Filigree and extremely small discs of all kinds are vital components across many different industries and applications.

Spacer rings and washers can have an insulating or sealing effect, but can also be used to compensate for tolerances between two components or to set a defined distance. Typical applications include use in fuel injection systems or in heat exchangers, and coding washers which are installed in sensors that perform important measuring tasks in industrial automation.

Spacers and washers can be manufactured with very complex geometries using the photo-chemical etching process. Extremely low positioning tolerances can be maintained, parts are absolutely free of stress and burrs. And thanks to the fact that deliberately weakened areas can be etched (partial etches or so called half-etches), they are very easy to separate in order to feed them to the next processing step.

Advantages at a glance

- Highest repeatability from the first to the last parts

- Complex structures can be fabricated

- Very low tooling costs — simple iteration loops due to design changes

- Delivery of parts on a roll – promoting cost-effective next-step processing

Our standards are industry leading

We operate in a world characterized by the tightest tolerances (hundredths of a millimeter), the finest structures, the thinnest metals, and the most complex geometries. We etch customized metal components to the tightest tolerances in large-scale industrial production volumes.

Our mission is to reach the highest customer satisfaction through excellent quality. In order to guarantee this to our customers, our processes are constantly monitored and further developed through strict quality controls. We are certified according to ISO 9001, IATF 16949, and ISO 14001.