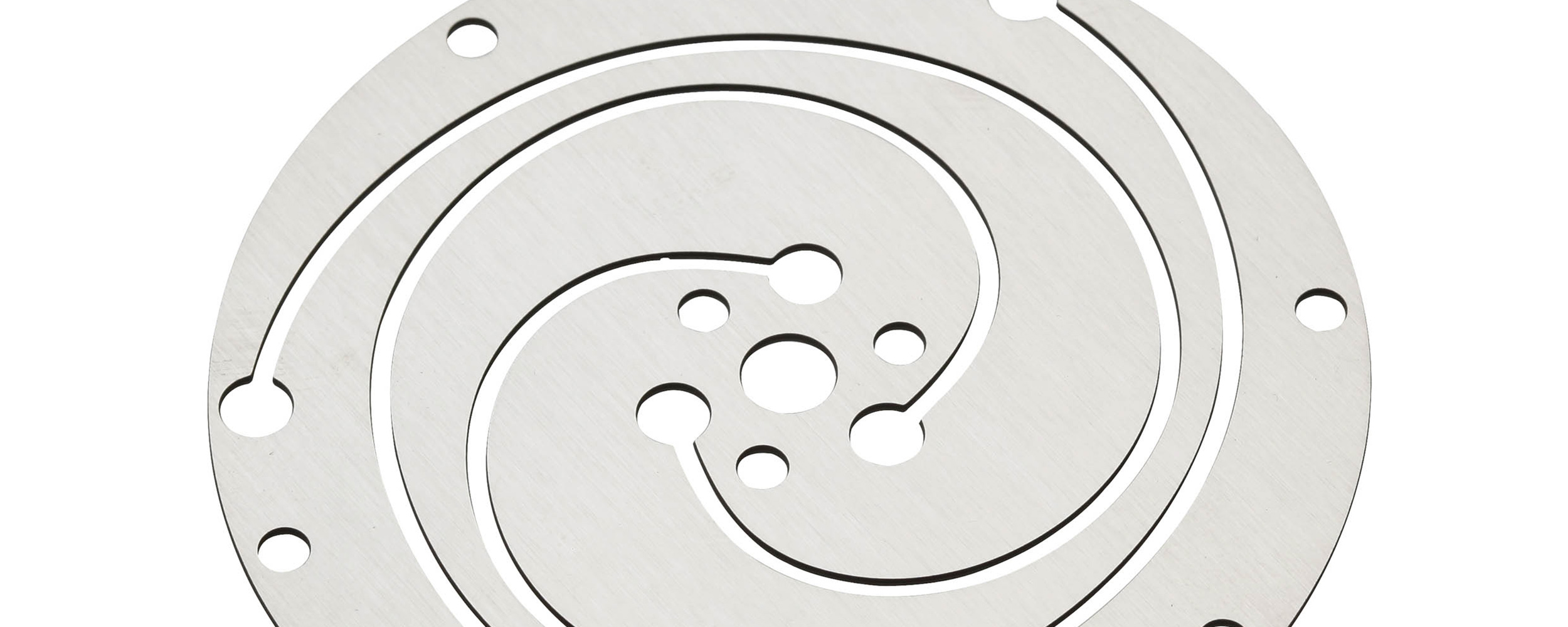

High-precision flat springs

Your challenge: to create a spring effect but with additional product properties.

Which advantages and benefits can be realized by our photo-chemical etching process?

The spring property can be specifically defined and implemented due to the high design freedom when using photo-chemical etching. Part design is created three-dimensionally. Thus, in addition to the spring effect, other product features can be created such as specific passages, positioning aids etc ...

Extremely hard and thin materials can be processed with our manufacturing technology. When the traditional stamping process is no longer appropriate, you can benefit from enormous degrees-of-freedom in the realization of your application and the selection of materials.

We deliver products according to your wishes "ready-to-use", coiled on tape, per sheet, or separated and absolutely free of dust, oil, and dirt.

Advantages at a glance

- Realization of complex designs

- Cost-effective tool production/design iterations

- Burr-free, stress-free, clean and flat parts

- Machining of thick starting materials and thinning them out

- Wide variety of metal grades

- Delivery according to your requirements

Our standards are industry leading

We operate in a world characterized by the tightest tolerances (hundredths of a millimeter), the finest structures, the thinnest metals, and the most complex geometries. We etch customized metal components to the tightest tolerances in large-scale industrial production volumes.

Our mission is to reach the highest customer satisfaction through excellent quality. In order to guarantee this to our customers, our processes are constantly monitored and further developed through strict quality controls. We are certified according to ISO 9001, IATF 16949, and ISO 14001.