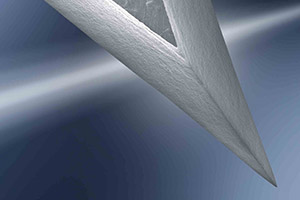

MICROMETAL SHOWS POWER OF NEXT GENERATION PHOTO-CHEMICAL ETCHING MAKING AN OPTHALMIC BLADE

(26th April 2023, Muellheim, Germany)

Leading photo-chemical etching (PCE) innovator, micrometal, is pleased to be able to demonstrate the power of its next generation precision metal processing technology following some recent work with a manufacturer of opthalmic devices incorporating surgical blades.

PCE offers several specific advantages when it comes to manufacturing intricate blades for eye surgery. Firstly, it allows for the creation of extremely precise and intricate blade designs with sharp edges and tight tolerances, ensuring the highest level of accuracy and consistency during surgery. This is particularly important for eye surgery, where even small variations in blade design can have a significant impact on patient outcomes.

Secondly, PCE can produce very thin blades, down to a few microns in thickness, which are required for many types of eye surgeries. These blades can be manufactured with no burrs or rough edges, ensuring smooth and precise cutting.

In addition, the PCE process is a chemical, non-contact process, which means that there is no physical force applied to the metal during manufacturing, reducing the risk of deformation or damage to the blade. This is particularly important when working with thin, delicate blades that require extreme precision.

Jochen Kern, Head of Sales and Marketing at micrometal says, “For manufacturers of intricate metal parts and components, choosing the right technology is crucial to ensure high-quality, accurate, and cost-effective production. micrometal’s next generation PCE process stands out as the go-to technology for several reasons, first and foremost because it offers unparalleled precision, enabling the creation of geometrically complex designs and shapes with tight tolerances that would be difficult or impossible to achieve with traditional manufacturing techniques. Additionally, PCE is highly versatile, allowing for the production of a wide range of metal types and thicknesses, and is relatively fast and cost-effective, with low tooling costs and short lead times and parts produced with no stress of burrs.”

micrometal has taken what is already a precise technology in PCE and enhanced it. The company’s process advantages mean that very small feature sizes of 25 microns can be produced, it can achieve a minimum hole diameter 80% of the material thickness, and single digit micron tolerances are attainable repeatably. It was this that attracted the ophthalmic device manufacturer which was specifically looking to make a surgical device and system for extremely delicate eye surgery for the removal of cataracts and vision correction. The blade is used to pierce the lens tissue of the eye with minimal tissue damage to aid better healing, allowing either mechanical removal of tissue or correction of internal eye features.

Kern continues, “We worked hard to achieve the extremely exacting tolerances that the ophthalmic device manufacturer required. The customer stated that our etched blades were the sharpest they had ever seen. PCE produces a very smooth and sharp cutting edge compared to conventional mechanical grinding of similar blades. Under a microscope, mechanically sharpened edges show fracturing and rough edges due to process issues and ‘brittle’ material conditions from work-hardening. micrometal’s combination of liquid photoresist and high-resolution tooling produces an extremely sharp cutting edge that does not ‘tear’ tissue.”

micrometal’s next generation PCE process uses a unique and patented wet paint etching system, the coating being 2 – 8 microns thick as opposed to traditional dry PCE coating which are 10 – 50 microns thick. Liquid photo-resist is more suitable for high precision production scenarios and results in higher reproduction accuracy.

micrometal’s high-resolution glass photomask tools are printed at 100,000 dpi, providing superior reproduction and resolution than film photo-tooling used in conventional chemical etching processes. The use of photo-tooling created on glass means the company can cater for applications such as the ophthalmic blade discussed that require extreme precision which traditional PCE cannot achieve. Glass photo tooling can attain tolerances in the range of 1-2 microns (and hole tolerances of < 1 micron can be achieved), and negates issues with distortion due to environmental factors such as humidity that are a constant problem when using film tooling.

Learn more about etching product design solutions.