MICROMETAL PROVIDES PARYLENE PROTECTIVE COATINGS FOR METAL PARTS & COMPONENTS

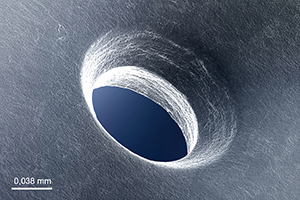

In the area of mesh and filter fabrication, the unique innovations that micrometal GmbH has developed to enhance standard and traditional PCE technologies have led to a number of possibilities in design, and tolerance attainment, until now impossible

MICROMETAL’S MARKET-LEADING EXPERTISE FOCUSES ON THE PRODUCTION OF MESHES & FILTERS USING PHOTO-CHEMICAL ETCHING

Photo-chemical etching (PCE) is renowned today as a metal processing technology that produces stress free, flat components by selective etching through a photo-resist mask. It is especially well suited

PHOTO-CHEMICAL ETCHING MICROFLUIDIC PLATES FOR FUELS CELLS, HEAT EXCHANGERS AND COOLING PLATES

Plate heat exchangers are found in numerous industrial applications, and essentially use metal plates to transfer heat between two fluids.

Precision Fair 2022 – 16 and 17 November 2022

Precision Fair 2002 – 16 and 17 November 2022 – in Brabanthallen, ‘s-Hertogenbosch (NL)

We look forward to seeing you at the Etchform stand 521 in hall 3.

PHOTO-CHEMICAL ETCHING FOR FUELS CELLS

Photo-chemical etching (PCE) is proving itself to be the most efficient and cost effective manufacturing technology available for the manufacture of plate heat exchangers.

Parylene protective coatings

Parylene is the ultimate protective coating for metal, and is used for protection of equipment, components, and surfaces in a range of end-use applications.

Costing photo-chemical etching

The photo-chemical etching can produce parts impossible to make using alternative processing technologies, but always the cost per part is crucial for manufacturing success.

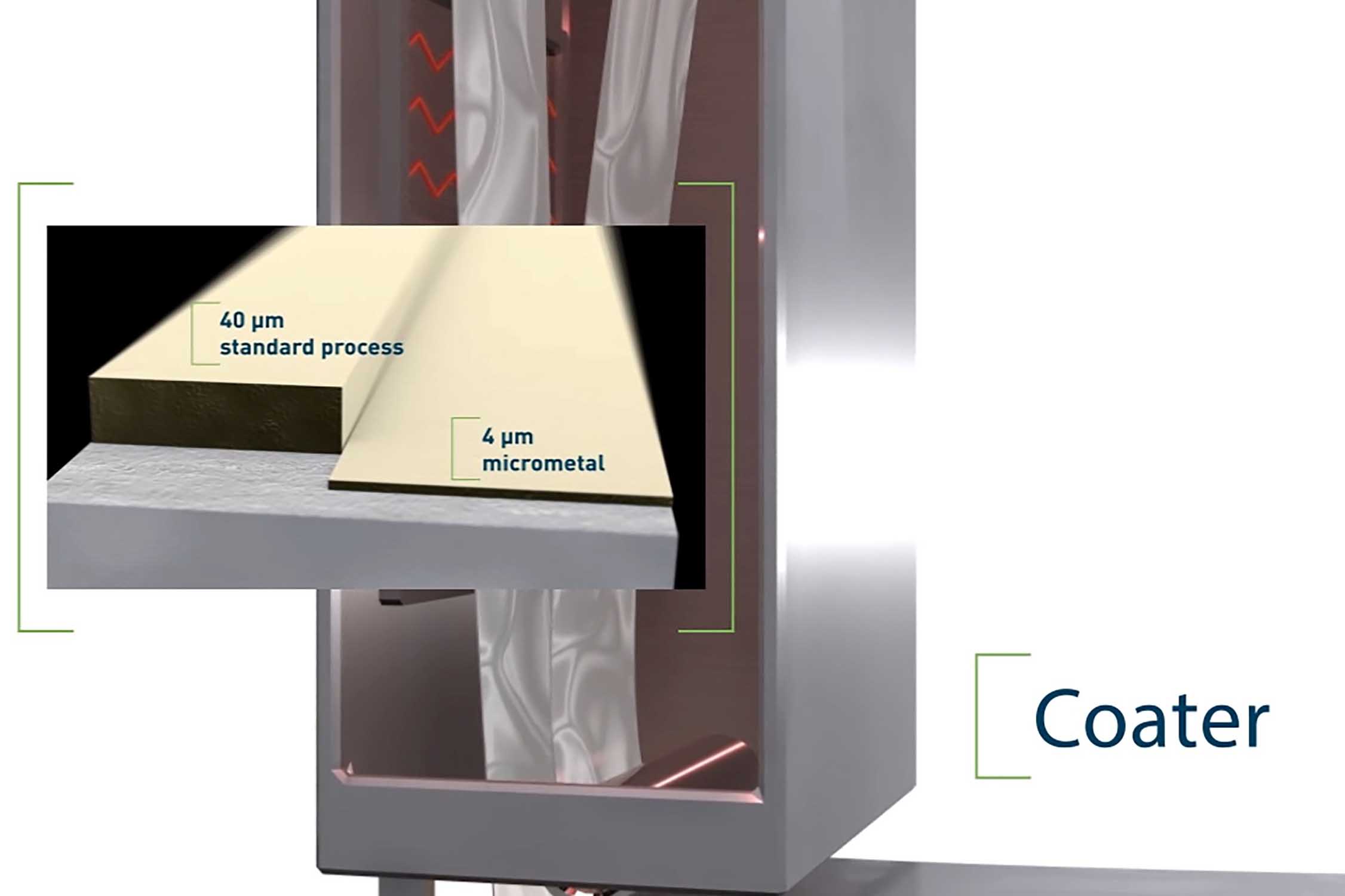

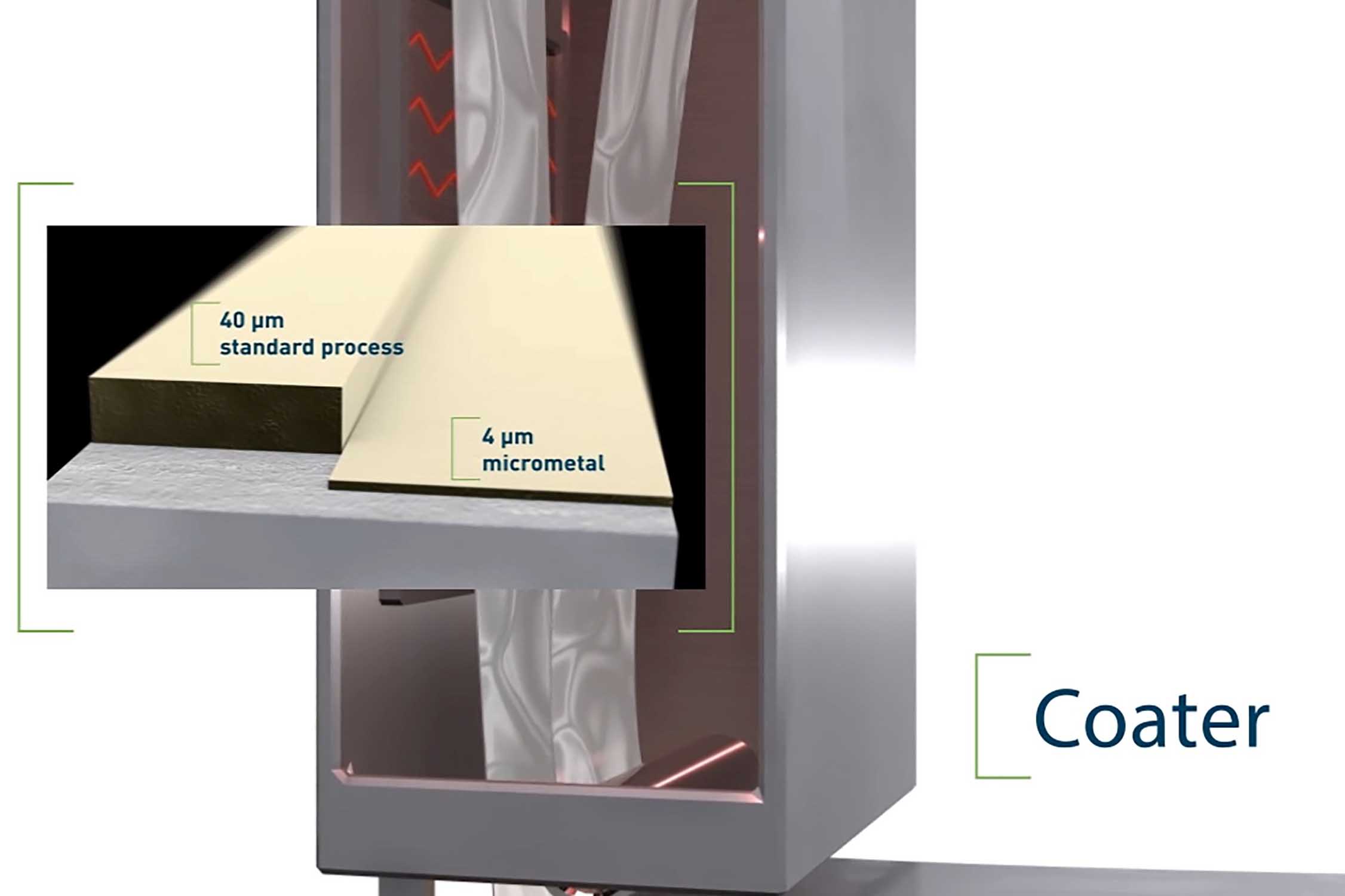

Tolerance attainment through process optimization

Tolerance attainment through process optimization.

Photo-chemical etching (PCE) is now seen throughout industry as the gold standard when the demand…

Benchmarking photochemical etching

The unique characteristics of photochemical etching overcome many of the issues, associated with more traditional metal cutting technologies….

Precision Titanium Parts & PCE

The demand from many sectors of industry today is for the use of light-weight but strong metals for a variety of applications. As such, titanium is often the material of choice for components used in end-use medical and aerospace products due to its high strength-to-weight ratio, its biocompatibility, corrosion resistance, extensive temperature range, and low […]