Free structurability

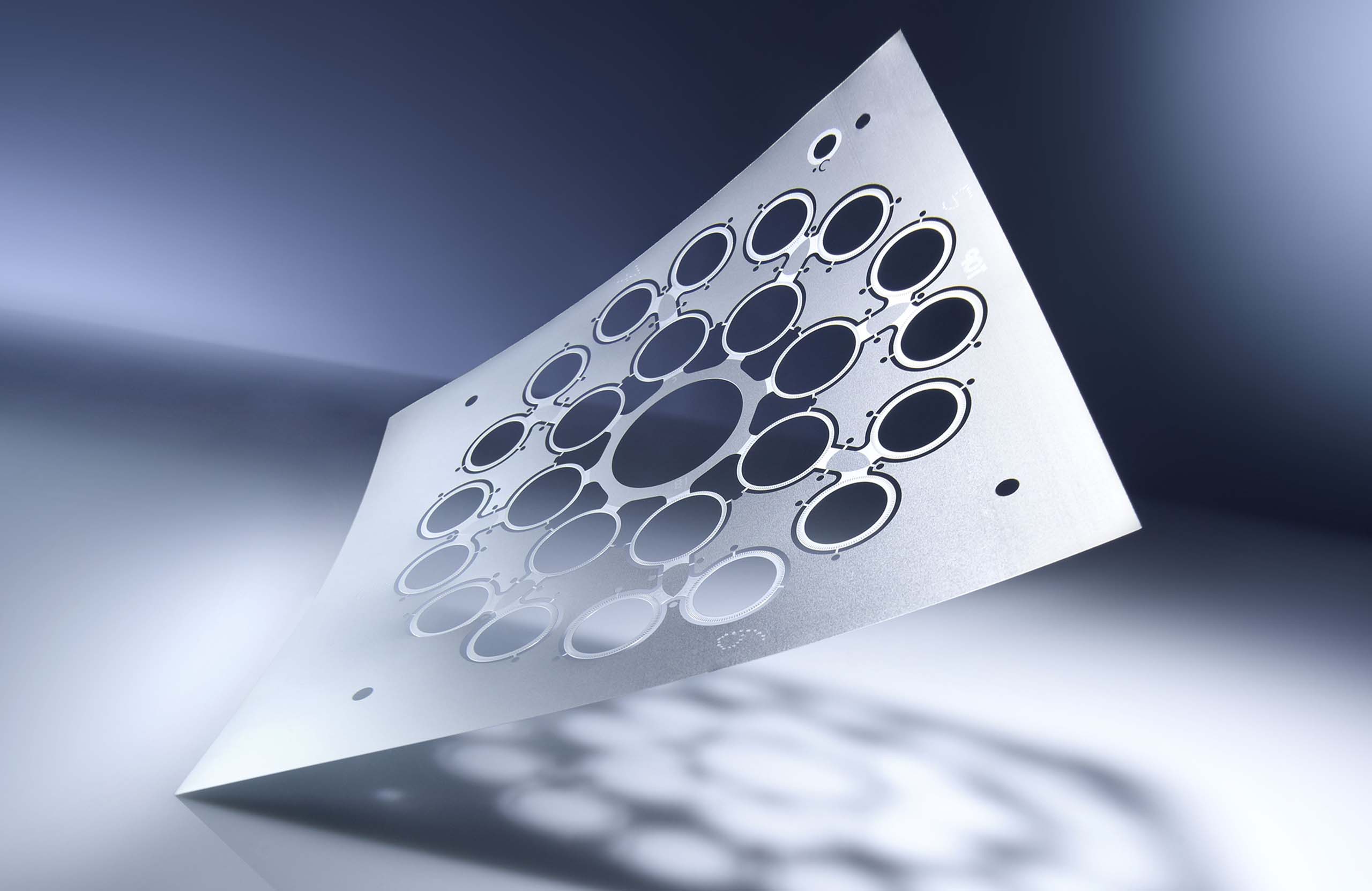

Filters, sieves and perforated strips are required by numerous industrial sectors, and customers often require complexity and the attainment of extremely high precision parameters. Our photo-chemical etching process is used for the manufacture of an array of filters and sieves for applications in the petrochemical industry, the food industry, the medical sector, and the automotive industry (which uses photo-etched filters due to their high tensile strength in fuel injection systems and in hydraulic devices). micrometal developed its photo-chemical etching technology to allow for the exact control of the etching process in 3 dimensions. This facilitates the creation of complex geometries, and when applied to the manufacture of meshes and sieves, dramatically reduced lead times. In addition, special features and various aperture shapes can be included in a single mesh with no increase in costs. We offer a decisive advantage — free structurability

Advantages at a glance

Your advantages at a glance:

- High tensile strength

- Burr- and stress-free parts

- Multiple features in one part at no extra cost

- Can be applied to hard to machine metals such as titanium

- Design Freedom

- Cost-effective tool production/design iterations

- Realization of complex designs (channel structures) without extra charge

Application: Etched perforated strips in the printing industry

micrometal Group has successfully manufactured screens from which a tens of meters long metal strip with conical holes which is wound on a rotating drum screen for a leading printer manufacturer is made.

The printer in which our photo-etched part is used is a high-volume sheet-fed paper printer. The section where micrometal Group’s part is placed is used to transport the sheet over multiple stages of the printing machine to eventually be printed again or disbursed.

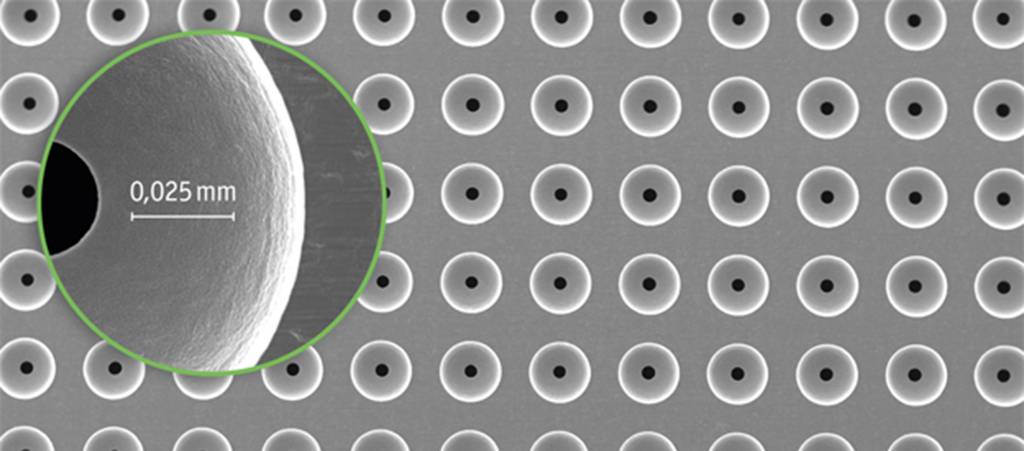

The conical holes in the screen need to be dimensional accurate. The long strips also need to be as straight as possible and they need to be free of burrs which could damage the paper and/or ink.

There are a number of technical advantages achieved through making this part using photo-chemical etching (PCE) as opposed to legacy metal fabrication processes such as stamping and laser cutting.

Learn more here

Our standards are industry leading

We operate in a world characterized by the tightest tolerances (hundredths of a millimeter), the finest structures, the thinnest metals, and the most complex geometries. We etch customized metal components to the tightest tolerances in large-scale industrial production volumes.

Our mission is to reach the highest customer satisfaction through excellent quality. In order to guarantee this to our customers, our processes are constantly monitored and further developed through strict quality controls. We are certified according to ISO 13485, IATF 16949, ISO 9001 and ISO 14001.